Maintenance

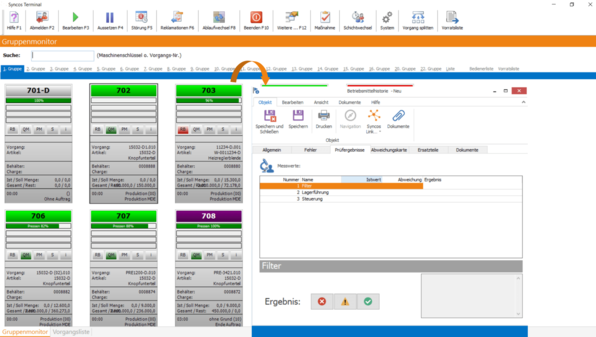

With SYNCOS you can manage all maintenance intervals and maintenance types – thin and reliable.

The most important features at a glance

- Eassy and clear management of tool-/ machine population including all corresponding information (stocktaking, history, labelling, documentations, etc.)

- Ongoing management of the machine use and tool use including the assurance of the maintenance interval compliance

- Implementation of different inspections according to freely definable plans and mandatory and own maintenance plans

- SYNCOS Today: Automated updates and display of tools and machines to be inspected at every program start to ensure constant machine availability

- Direct selection of machines and tools without detours

- Minimized maintenance effort because of pre-definitions on type level

- Evaluations, reports and analyses (layout adjustable by integrated report designer) support the user within the consistent realization (dunning lists, checklists, monitoring cards, etc.) for cost control

- Whole integration into SYNCOS Control Panel, SYNCOS Scheduling Board and the terminal

Guarantee maintenance scheduling at 100%

By deciding for SYNCOS Maintenance, you minimize downtimes and enjoy a powerful tool, which helps to put your plans consequently into practice and to reduce effectively maintenance costs.

Obviously, your maintenance due dates are completely integrated into other SYNCOS modules from the detailed planning to the control panel and graphically visualized. Transitional arrangements for maintenance intervals can be adapted to your requirements.

Reactive maintenance is outdated with SYNCOS. You rather do condition-based maintenance work in the future. Permanent data acquisition and data processing allow stalling the change of components as far as possible. So you can use your components shortly before their breakdown, reduce your costs and downtimes and maximize the use of investment costs.